Warehousing

Efficiency Elevated

Warehousing

Efficiency Elevated

Warehousing

Efficiency Elevated

Warehousing

Efficiency Elevated

Processes

Processes

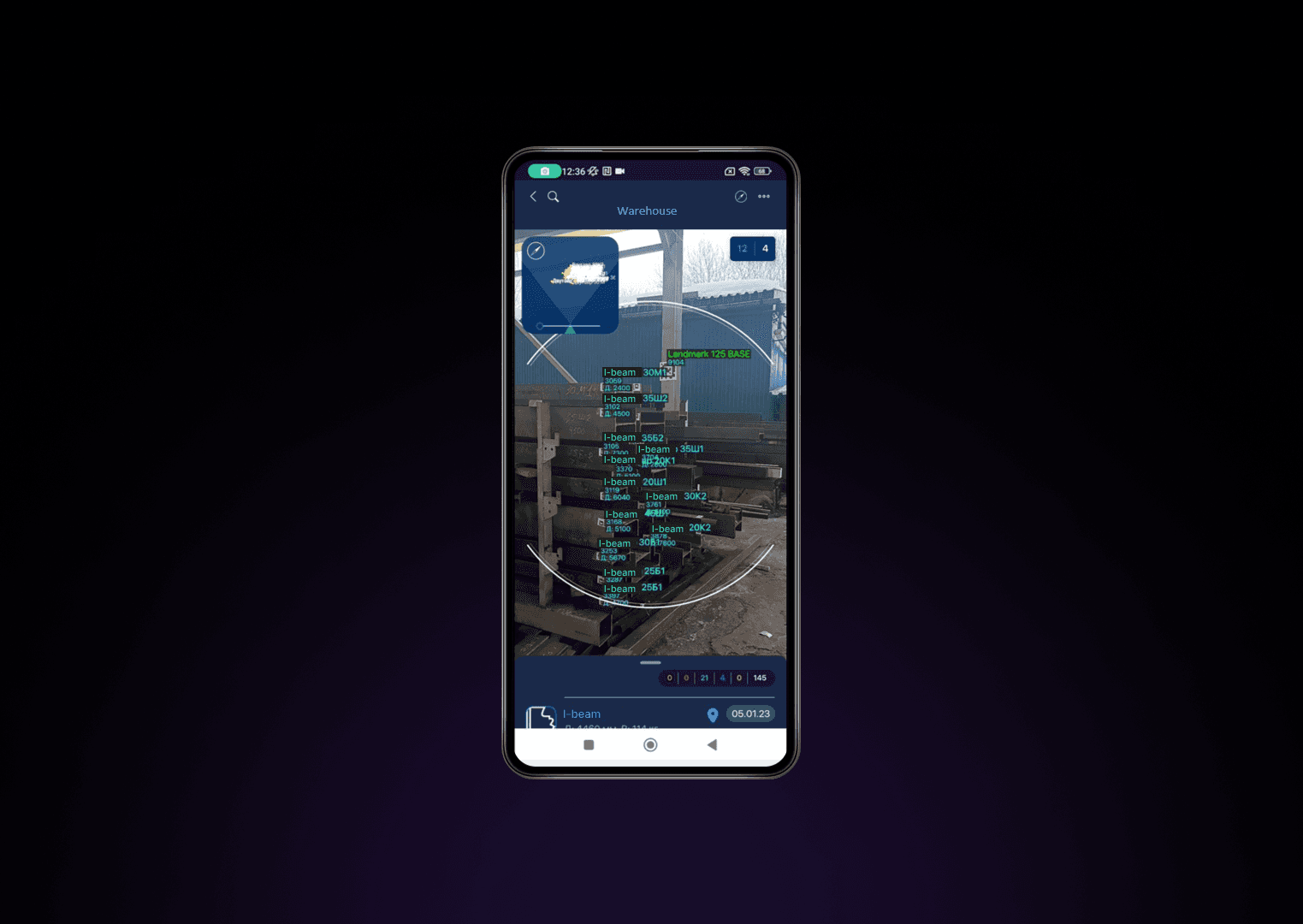

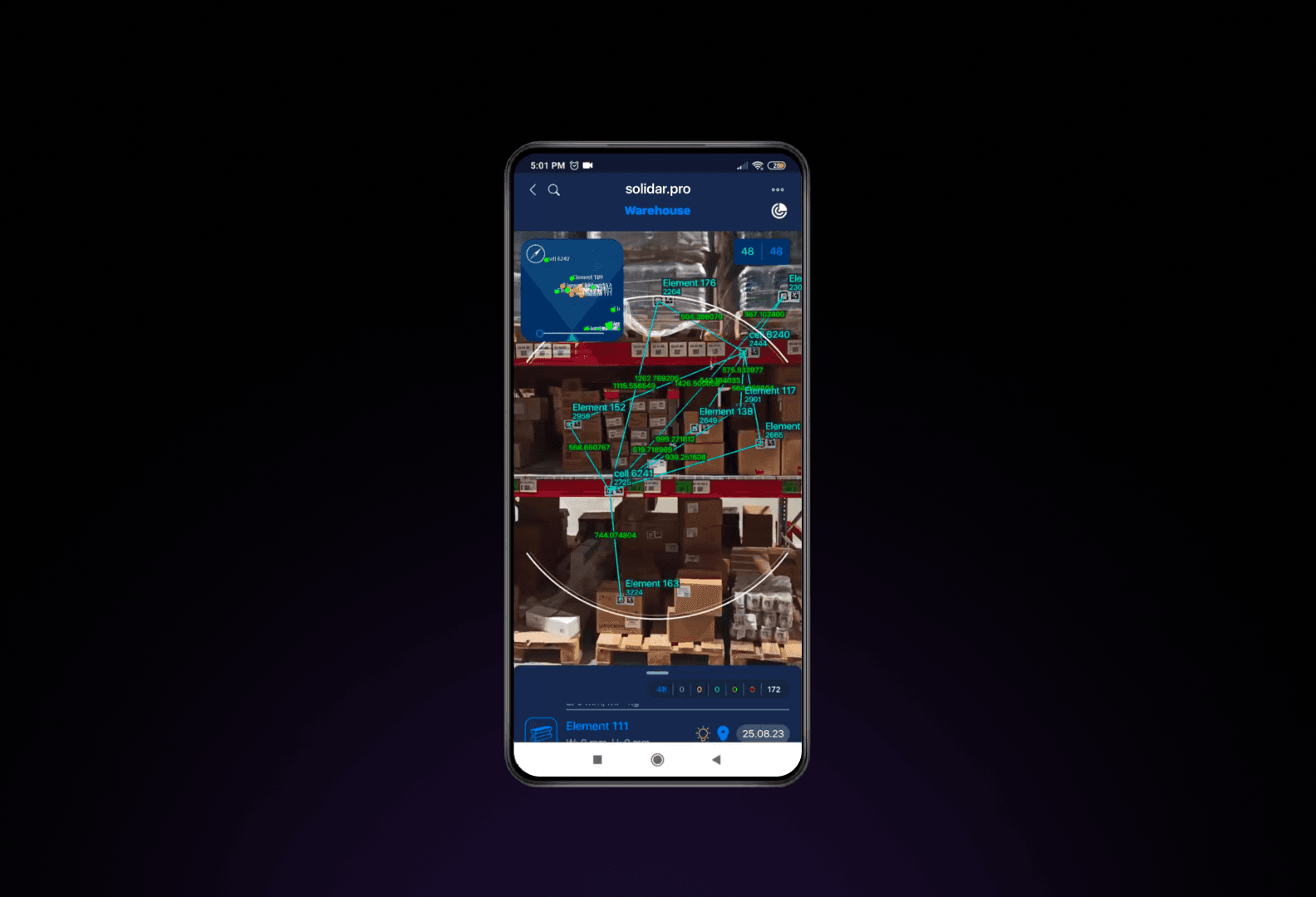

SolidAR’s Warehousing Solution streamlines the steps needed to complete tasks by identifying multiple* markers simultaneously, automatically feeding the system with accurate Real-Time data:

SolidAR’s Warehousing Solution streamlines the steps needed to complete tasks by identifying multiple* markers simultaneously, automatically feeding the system with accurate Real-Time data:

SolidAR’s Warehousing Solution streamlines the steps needed to complete tasks by identifying multiple* markers simultaneously, automatically feeding the system with accurate Real-Time data:

Location of item

Location of item

Depth of item on shelf – identified at time of scan, even if other items are subsequently placed in front.

Depth of item on shelf – identified at time of scan, even if other items are subsequently placed in front.

Route mapping to the required item

Route mapping to the required item

Automatic inventory control

Automatic inventory control

Inventory control

Inventory control

Multiple markers can be simultaneously identified

Multiple markers can be simultaneously identified

Orderly storage

Orderly storage

Route mapping to the required item

Route mapping to the required item

Remote inventory control in real-time

Remote inventory control in real-time

Items can be organised ready for logistics, according to delivery route, assembly scheme etc.

Items can be organised ready for logistics, according to delivery route, assembly scheme etc.

Space & Equipment

Space & Equipment

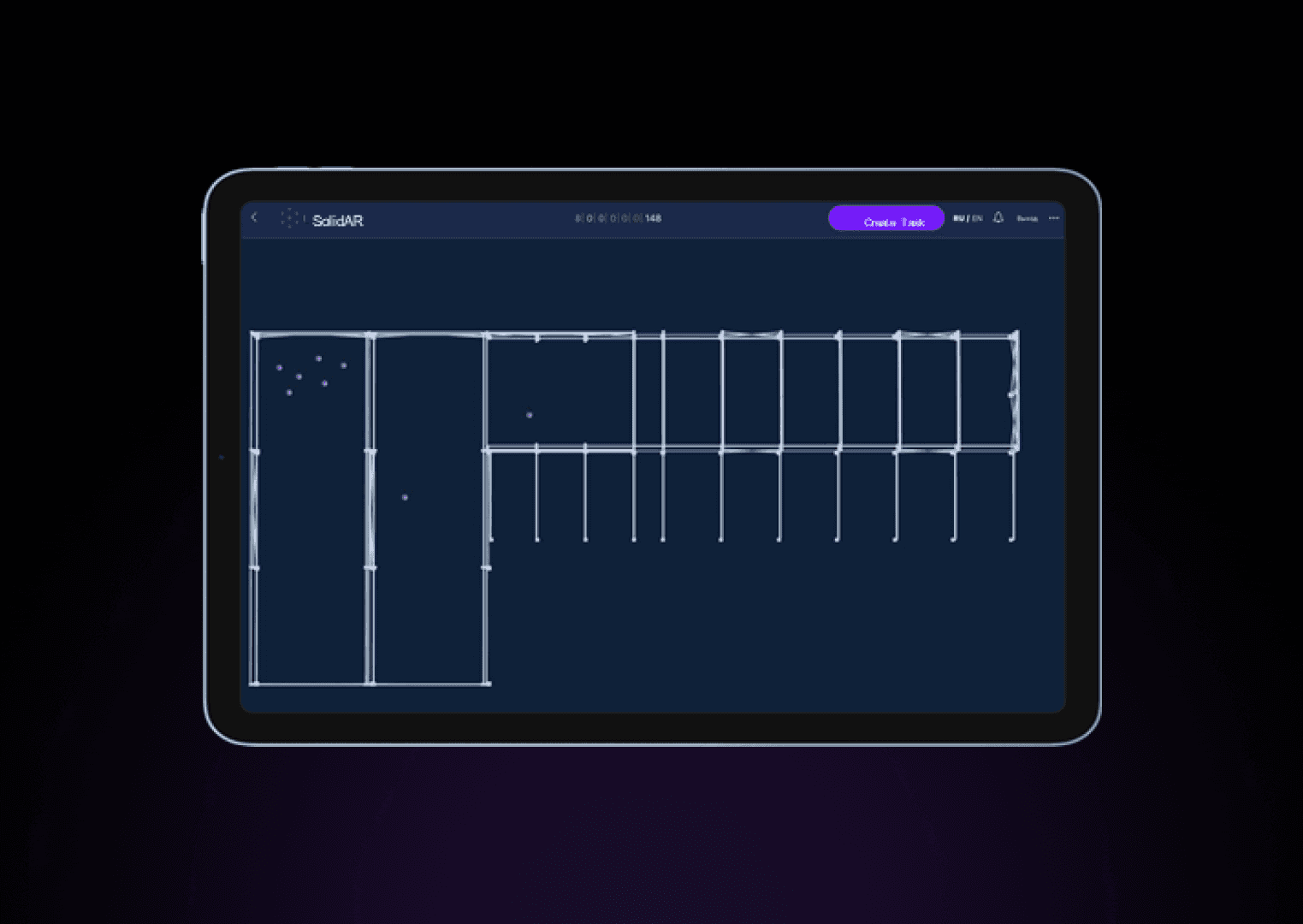

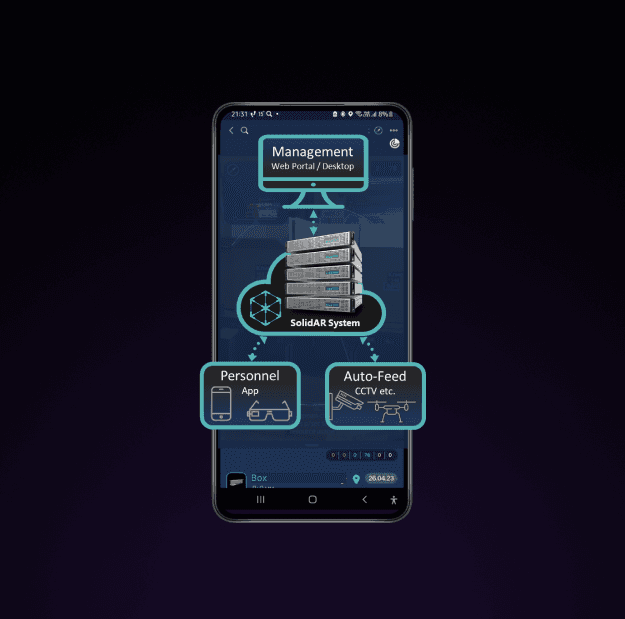

SolidAR creates a 3D Digital Twin of the warehouse to ascertain the dimensions of the space and racking

SolidAR creates a 3D Digital Twin of the warehouse to ascertain the dimensions of the space and racking

SolidAR creates a 3D Digital Twin of the warehouse to ascertain the dimensions of the space and racking

Fixed markers on the racking / structure give static coordinates for the items to be referenced to

Fixed markers on the racking / structure give static coordinates for the items to be referenced to

Fixed markers on the racking / structure give static coordinates for the items to be referenced to

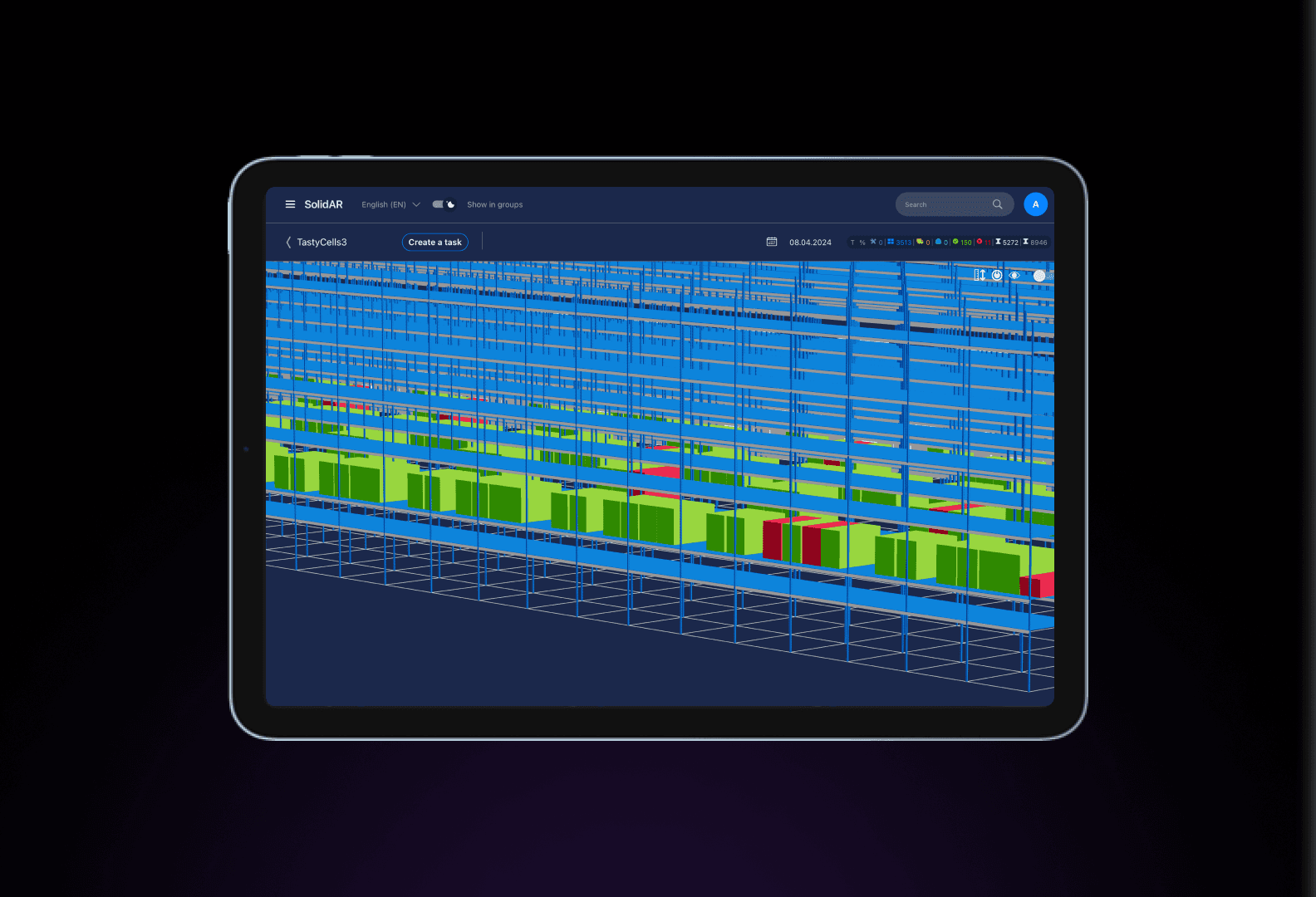

Control markers can also be applied to moving objects; cranes, forklifts, crates etc., enabling advanced analytics

Control markers can also be applied to moving objects; cranes, forklifts, crates etc., enabling advanced analytics

Control markers can also be applied to moving objects; cranes, forklifts, crates etc., enabling advanced analytics

Warehouse mapping

Warehouse mapping

Fixed markers to give static coordinates

Fixed markers to give static coordinates

Fixed markers to give static coordinates

Control markers are applied to moving objects (cranes, forklifts, crates, etc.)

Control markers are applied to moving objects (cranes, forklifts, crates, etc.)

Control markers are applied to moving objects (cranes, forklifts, crates, etc.)

High long range detection accuracy

High long range detection accuracy

High long range detection accuracy

Can be integrated with existing surveillance systems

Can be integrated with existing surveillance systems

Can be integrated with existing surveillance systems

Order Picking/Fulfilment

Order Picking/Fulfilment

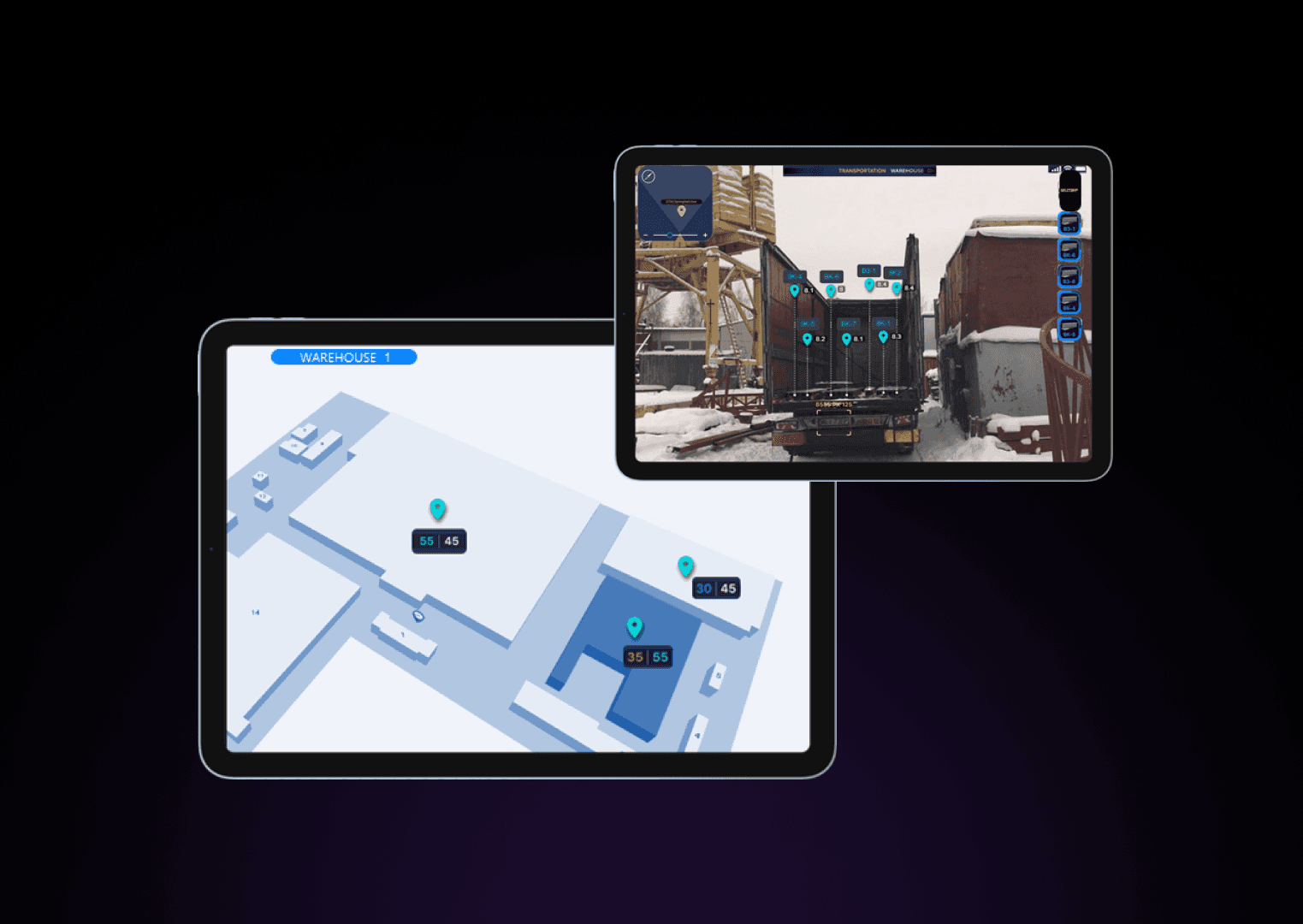

SolidAR effortlessly guides the warehouse operation through the entire fulfilment process, from receiving the order, through to the item correctly leaving the warehouse.

SolidAR effortlessly guides the warehouse operation through the entire fulfilment process, from receiving the order, through to the item correctly leaving the warehouse.

SolidAR effortlessly guides the warehouse operation through the entire fulfilment process, from receiving the order, through to the item correctly leaving the warehouse.

Management have total operational overview and can:

Management have total operational overview and can:

Management have total operational overview and can:

Organise tasks ready for logistics, according to delivery route, assembly scheme etc.

Organise tasks ready for logistics, according to delivery route, assembly scheme etc.

Assign tasks to personnel

Assign tasks to personnel

Remotely monitor personnel as they perform their duties

Remotely monitor personnel as they perform their duties

Receive and utilise real-time inventory data

Receive and utilise real-time inventory data

Benefit from automated end-to-end documentation

Benefit from automated end-to-end documentation

Personnel have increased efficiency due to:

Personnel have increased efficiency due to:

Personnel have increased efficiency due to:

Route mapping to, and identification of correct items

Route mapping to, and identification of correct items

In-App guidance ensuring item is properly despatched

In-App guidance ensuring item is properly despatched

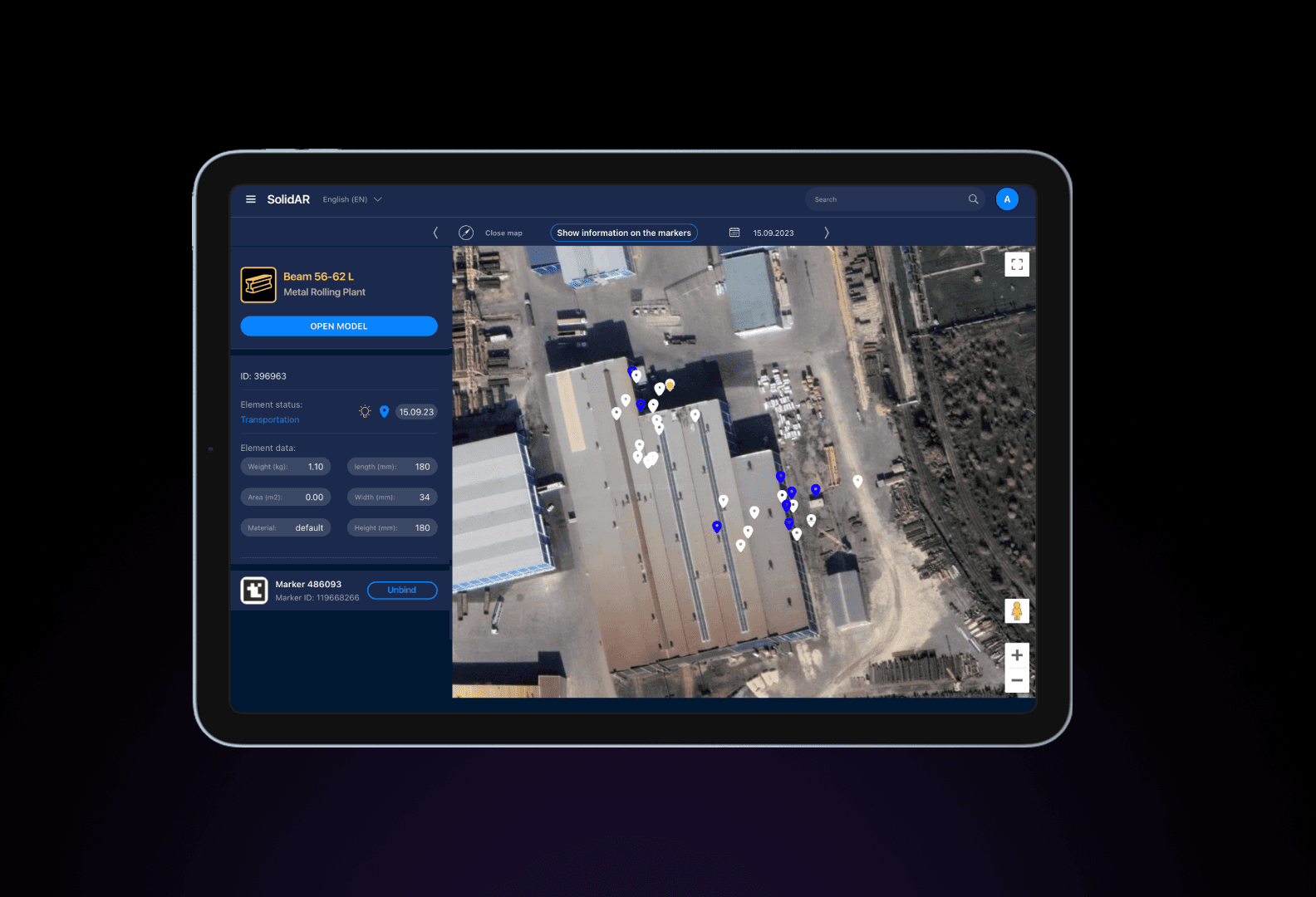

Production to site

Production to site

Items are transported from the manufacturing facility to the end site for storage / assembly in as many steps as needed, dependent on the logistic challenges of each situation; and the SolidAR Warehousing and Transport Solutions as described earlier can be utilised in all steps to streamline processes to provide real-time status data for all project participants.

Items are transported from the manufacturing facility to the end site for storage / assembly in as many steps as needed, dependent on the logistic challenges of each situation; and the SolidAR Warehousing and Transport Solutions as described earlier can be utilised in all steps to streamline processes to provide real-time status data for all project participants.

Items are transported from the manufacturing facility to the end site for storage / assembly in as many steps as needed, dependent on the logistic challenges of each situation; and the SolidAR Warehousing and Transport Solutions as described earlier can be utilised in all steps to streamline processes to provide real-time status data for all project participants.

Customisation

Customisation

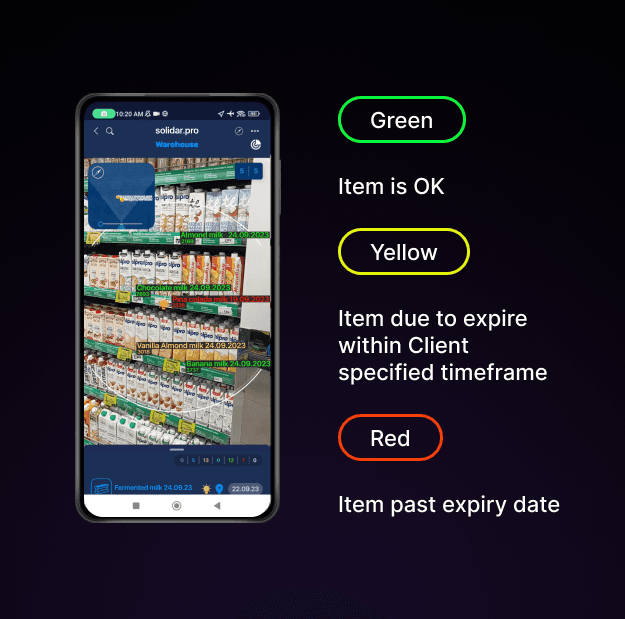

We can integrate to fit any Client’s needs; below shows example of configuration for expiration dates:

We can integrate to fit any Client’s needs; below shows example of configuration for expiration dates:

We can integrate to fit any Client’s needs; below shows example of configuration for expiration dates:

There is no limit to the number of markers that can be simultaneously identified

There is no limit to the number of markers that can be simultaneously identified

There is no limit to the number of markers that can be simultaneously identified